The heavy-duty semi-automatic logistics bench system is cost-effective for nurseries and potted plant operations. It allows flexible movement of benches along rails, optimizing space and reducing investment costs compared to fully automated systems.

1. Components

This system consists of a bench mechanism, vertical support mechanism, table Inlet and outlet mechanism, electrical control (footprint valve and electrical accessories), sub-control cabinet, galvanized bolts, nuts, gaskets, and other fittings parts.

1.1 Tables

Depending on the intended use and load requirements, the table offers versatile options, including a mesh or ebb-and-flow style design. Its sturdy construction features an aluminum alloy outer frame paired with reinforced steel grating. For internal components, users can choose from expanded metal, straight cross members, or metal mesh, ensuring adaptability to various applications.

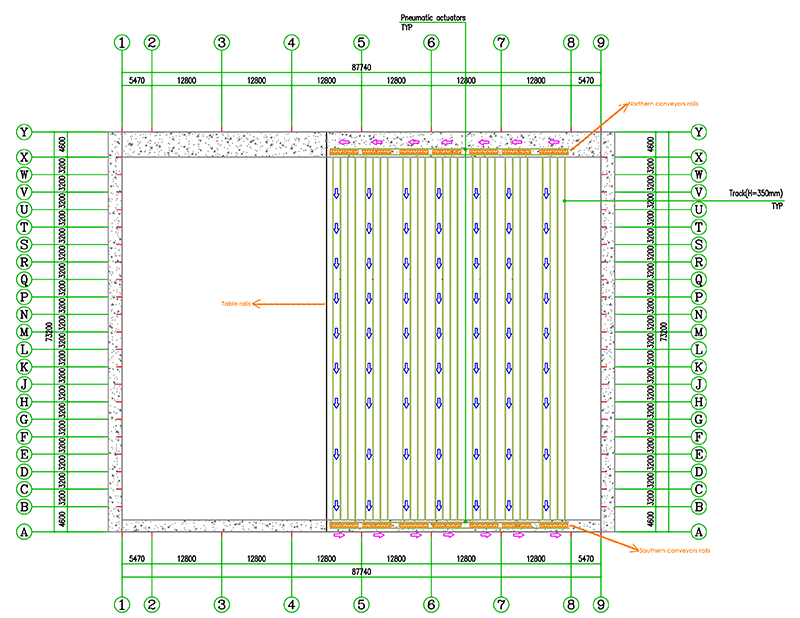

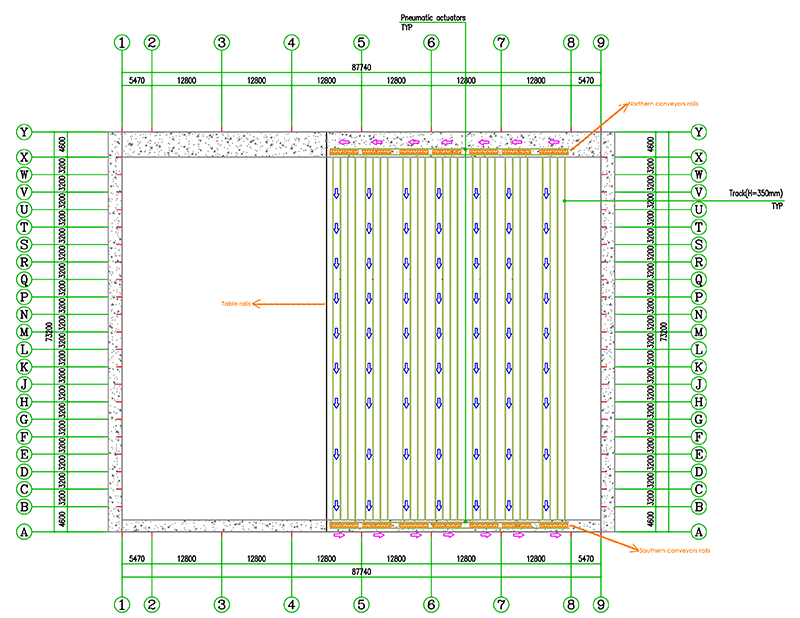

1.2 Support rails and foundation

*Vertical table rails (From north to south): The ground track consists of 4 reinforced support rails, capable of withstanding loads of 169.5kg/m² to 212kg/m², with a rail height of 0.35m.

*Horizontal conveyor rails (north and south).

*Rail leg foundation: Concrete footing or strip foundation along rail legs.

3. Operation Principle

3. Operation Principle

The bench will first be lifted from the northern conveyor rail onto the table rails by pneumatic or electric lifters. Once on the table rails, it will be manually pushed to its desired position. Finally, pneumatic or electric lifters will transfer the bench from the table rails to the southern conveyor rail.

4. Table transition from the conveyor/table rail system to the table rail/conveyor system?

1. Corner pivoting solution

2. Pneumatic/electrical lifters and linear actuator